Traditional paper-based inspections create numerous operational challenges that impact quality control and safety compliance:

Lost or damaged paper checklists result in incomplete inspection records

Illegible handwriting makes it difficult to identify critical defects

Manual data entry delays corrective action on failed inspection items

Missing photos provide insufficient evidence for non-compliance issues

Disconnected inspection data prevents trend analysis across multiple sites

Paper forms make it nearly impossible to track inspection completion rates, identify recurring quality issues, or ensure inspectors follow standardized procedures consistently. Organizations struggle to maintain audit trails required for ISO certifications, safety regulations, and customer quality requirements.

Digital inspection apps eliminate these pain points by providing structured checklists, automatic photo documentation, real-time issue tracking, and centralized reporting that transforms reactive quality control into proactive compliance management.

Why Digital Inspection Apps Transform Quality Management

Generic inspection software forces your team to adapt their proven inspection procedures to fit rigid formats that don't match your specific quality criteria, safety protocols, or industry compliance requirements.

Custom inspection apps align perfectly with:

Your organization's specific inspection checklists and quality standards

Industry-specific compliance requirements and certification criteria

Unique defect categorization and severity rating systems

Existing corrective action workflows and approval processes

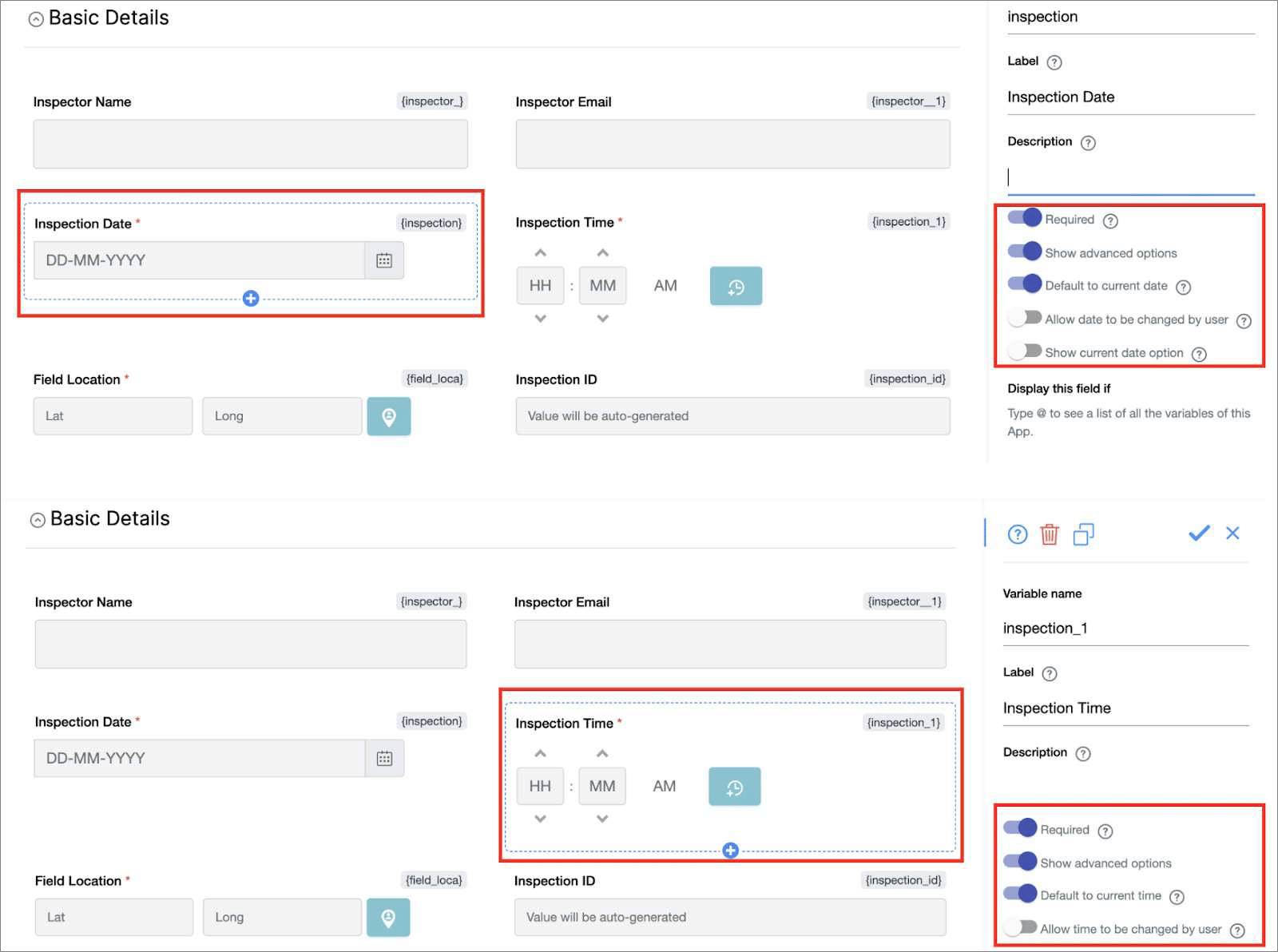

No-code development enables quality managers and safety officers who understand inspection requirements firsthand to build solutions that match their exact operational needs. This eliminates miscommunication with external developers who lack domain expertise in your industry's quality standards.

Key advantages include elimination of data transcription errors, immediate visibility into failed inspections, automated routing of corrective actions to responsible parties, complete audit trails for compliance documentation, and real-time dashboards showing inspection completion rates and defect trends across all locations.

App Structure for Inspection Management System

App 1: Inspection Checklists Master

Section: Checklist Details

Field Type | Label | Configurations |

|---|---|---|

Unique ID | Checklist ID | Auto-generate, Prefix: "CHK-", Start from: 101 |

Single Line Text | Checklist Name | Required: Yes, Character Limit: 150 |

Dropdown | Inspection Category | Options: Safety, Quality Control, Equipment, Facility, Process Audit, Compliance; Required: Yes |

Dropdown | Inspection Frequency | Options: Daily, Weekly, Monthly, Quarterly, Annual, On-Demand; Required: Yes |

Multi-line Text | Inspection Purpose | Character Limit: 300, Placeholder: Describe the objective of this inspection |

Section: Checklist Items (Copyable Section)

Field Type | Label | Configurations |

|---|---|---|

Single Line Text | Check Point Description | Required: Yes, Character Limit: 200 |

Dropdown | Category | Options: Critical, Major, Minor; Required: Yes |

Multi-line Text | Inspection Criteria | Required: Yes, Character Limit: 500, Placeholder: Specific requirements for passing |

Rich Text Editor | Reference Standards | Link insertion enabled, Placeholder: Relevant safety codes or quality specifications |

Section: Approval Requirements

Field Type | Label | Configurations |

|---|---|---|

Dropdown | Requires Manager Approval | Options: Yes, No; Default: No |

Single Line Text | Responsible Department | Character Limit: 100 |

Number | Target Completion Time (Minutes) | Minimum value: 5 |

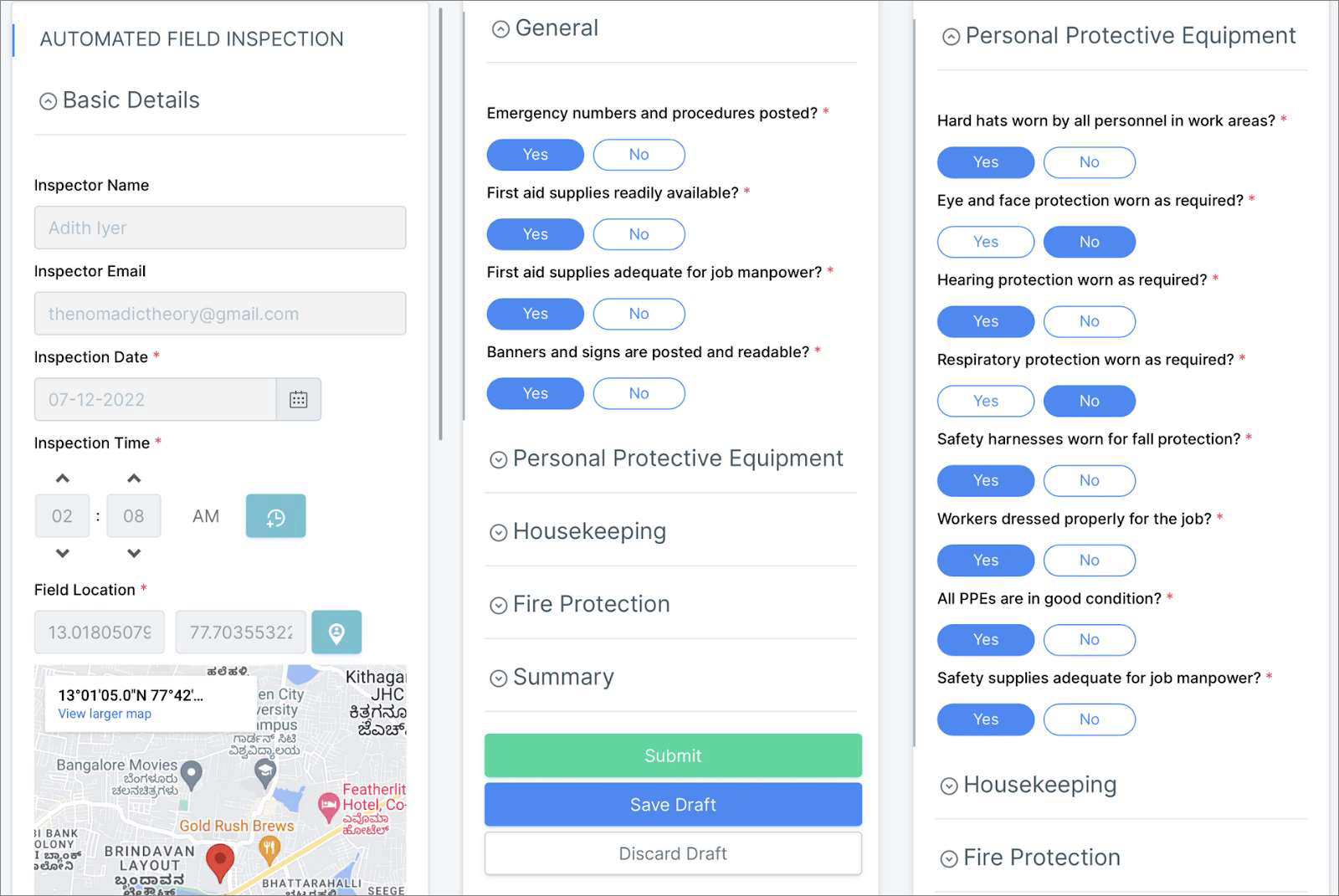

App 2: Inspection Records

Section: Inspection Information

Field Type | Label | Configurations |

|---|---|---|

Unique ID | Inspection ID | Auto-generate, Prefix: "INS-", Start from: 1001 |

Data from App | Select Inspection Checklist | Source: Inspection Checklists Master, Display: Checklist Name, Fetch: Checklist ID, Items |

Single Line Text | Inspector Name | Required: Yes, Auto-fill from logged-in user |

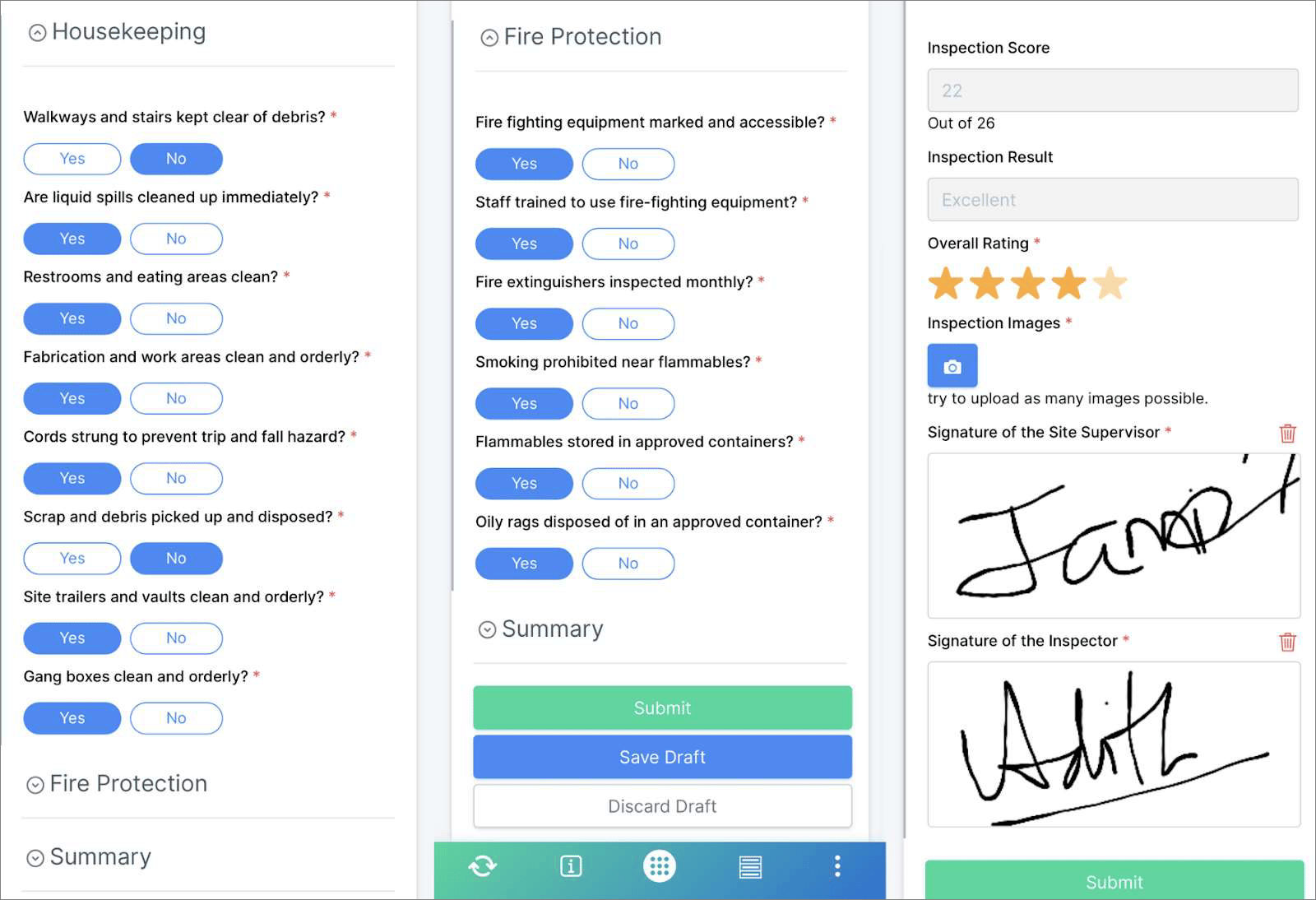

Date Time | Inspection Date | Auto-capture: Yes, Required: Yes |

Location | Inspection Location | Auto-capture GPS, Required: Yes |

Section: Site/Asset Details

Field Type | Label | Configurations |

|---|---|---|

Dropdown | Facility/Site Name | Options: Plant A, Plant B, Warehouse 1, Distribution Center, Corporate Office |

Single Line Text | Equipment/Area ID | Character Limit: 50, Placeholder: Equipment tag or area designation |

Camera | Site Photo | Allow multiple: Yes, Maximum: 3 |

Section: Inspection Checklist Results (Dynamic from Master Checklist)

Field Type | Label | Configurations |

|---|---|---|

Single Line Text | Checkpoint Name | Auto-filled from master checklist |

Dropdown | Inspection Result | Options: Pass, Fail, Not Applicable; Required: Yes |

Camera | Evidence Photos | Allow multiple: Yes, Maximum: 5 per checkpoint |

Multi-line Text | Observations/Notes | Character Limit: 500 |

Dropdown | Defect Severity | Options: Critical, Major, Minor; Show only when Result = Fail |

Section: Overall Assessment

Field Type | Label | Configurations |

|---|---|---|

Formula | Pass Rate Percentage | Formula: (Number of Pass / Total Checkpoints) × 100 |

Dropdown | Overall Status | Options: Approved, Approved with Conditions, Rejected; Required: Yes |

Rich Text Editor | Inspector Comments | Allow formatted text, Character Limit: 1000 |

Signature | Inspector Signature | Required: Yes |

Section: Corrective Actions (Conditional: Show when any checkpoint fails)

Field Type | Label | Configurations |

|---|---|---|

Multi-line Text | Corrective Action Required | Required: Yes, Character Limit: 500 |

Single Line Text | Assigned To | Required: Yes, Character Limit: 100 |

Date | Target Completion Date | Required: Yes, Minimum: Today's date |

Dropdown | Priority Level | Options: Urgent, High, Medium, Low; Required: Yes |

App Interconnection: The Inspection Records app connects to Inspection Checklists Master through the "Data from App" block, automatically loading the complete checklist with all checkpoint descriptions and criteria when an inspector selects a checklist. This ensures every inspection follows standardized procedures while allowing real-time recording of results and corrective actions.

Step-by-Step Guide to Building Your Inspection System

Step 1: Create Workspace and Master Checklists App

Get started by establishing your workspace and creating the "Inspection Checklists Master" app using the app builder interface. Configure the Unique ID block to generate checklist IDs automatically. Build the checklist items section as a copyable section so quality managers can add multiple inspection checkpoints within each checklist, creating comprehensive inspection lists that cover all quality criteria, safety requirements, or compliance standards relevant to each inspection type.

Step 2: Design Inspection Records App with Checklist Integration

Create the "Inspection Records" app and add the Data from App block configured to pull complete inspection checklists. When inspectors select a checklist, the app automatically loads all checkpoint descriptions, inspection criteria, and severity categories. This eliminates manual checklist creation during inspections and ensures every inspector follows identical procedures regardless of experience level, maintaining consistency across all inspection activities and locations throughout your organization.

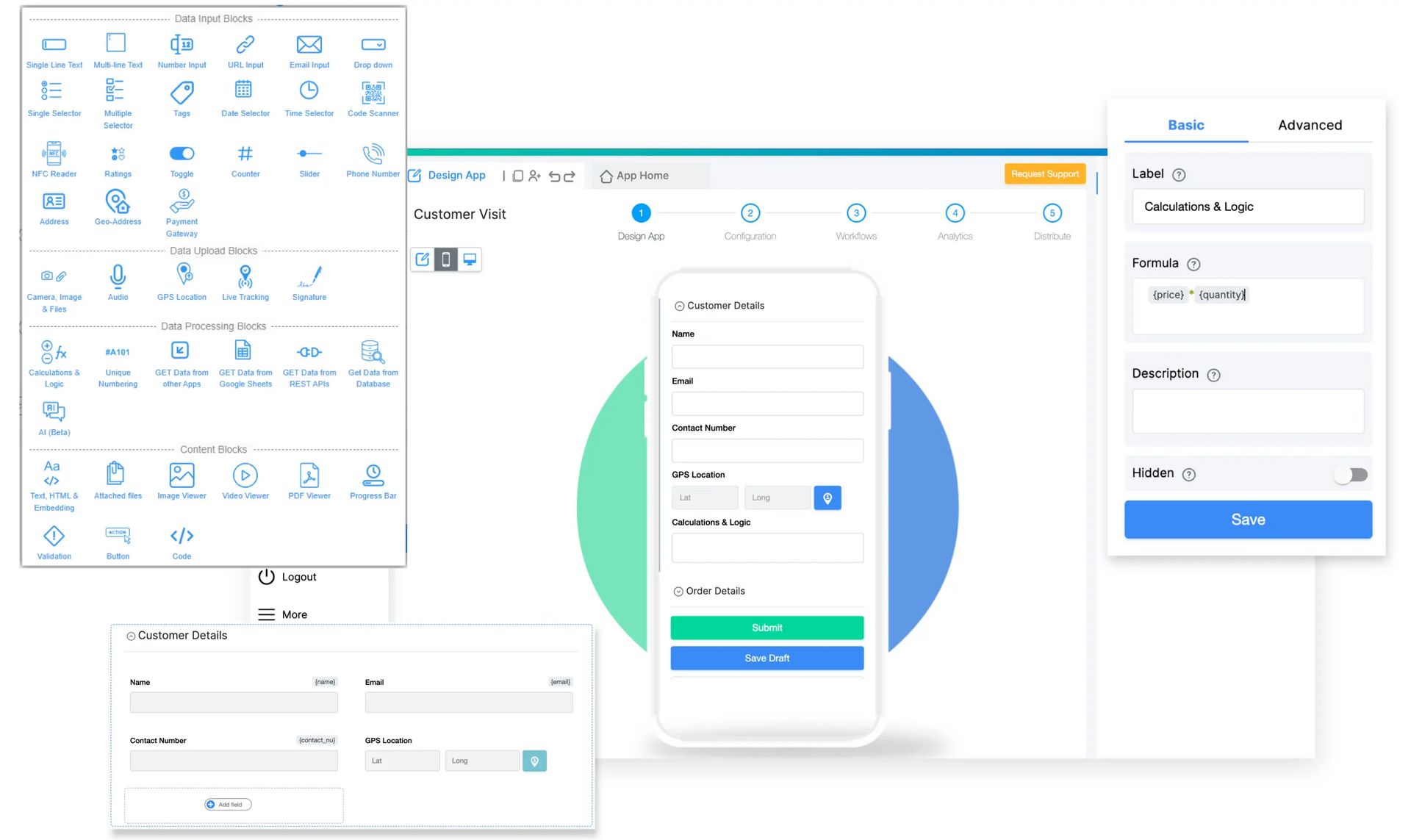

Step 3: Configure Dynamic Checklist with Pass/Fail Options

Set up conditional sections that display defect severity dropdowns and corrective action fields only when inspection results are marked as "Fail." Use Dropdown blocks with Pass/Fail/Not Applicable options for each checkpoint. Add Camera blocks allowing inspectors to capture multiple evidence photos documenting both compliant conditions and identified defects. Configure Multi-line Text fields for detailed observations that provide context beyond simple pass/fail ratings.

Step 4: Implement Automatic Scoring and Status Calculations

Add Formula blocks that automatically calculate pass rate percentages by counting checkpoints marked as "Pass" divided by total checkpoints multiplied by 100. Create conditional formulas that determine overall inspection status based on critical checkpoint failures versus minor defects. Build calculations that assign risk scores based on the number and severity of failed items, helping management prioritize corrective actions and resource allocation for addressing the most significant quality or safety issues discovered during inspections.

Step 5: Set Up Automated Failure Notifications

Configure workflows that trigger immediately when critical checkpoints fail or when overall inspection status is "Rejected." Create automated email alerts to quality managers, safety officers, and facility supervisors with inspection details, failed checkpoint summaries, and attached evidence photos. Set up WhatsApp notifications for urgent safety violations requiring immediate attention. Build escalation workflows that send reminders if corrective actions remain incomplete past target dates, ensuring accountability for resolving identified issues.

Step 6: Configure Approval Workflows for Critical Inspections

Implement approval workflows requiring manager review before inspections marked as "Approved with Conditions" or "Rejected" are finalized. Configure multi-level approvals where facility managers review failed inspections before quality directors receive notifications. Set up conditional approval routing based on defect severity, sending critical safety violations directly to executive management while routing minor quality issues through departmental supervisors. Add digital signature requirements from both inspectors and approvers to maintain audit trail compliance.

Step 7: Build Real-Time Inspection Dashboards and Reports

Create comprehensive analytics dashboards displaying inspection completion rates by facility, pass/fail trends over time, and most frequently failed checkpoints. Use bar graphs to visualize defect distribution by category and severity level. Generate pie charts showing the proportion of approved versus rejected inspections across different inspection types. Build custom reports that automatically compile monthly compliance statistics, recurring defect patterns, and corrective action completion rates for quality management review meetings and regulatory audit preparation.

Step 8: Configure Role-Based Permissions and Data Security

Establish role-based access control ensuring inspectors can complete inspections but cannot modify master checklists or delete historical inspection records. Allow quality managers to create and edit checklists while restricting access to sensitive compliance data for general staff. Give auditors read-only access to all inspection records with complete audit trail visibility. Configure facility managers to view only inspections for their assigned locations while executives access consolidated data across all sites, maintaining data security while enabling appropriate oversight at each organizational level.

Real-World Industry Applications

Manufacturing operations use quality control inspections to verify product specifications, identify defects before shipment, and maintain ISO 9001 certification compliance. The app tracks defect rates by production line, identifies recurring quality issues requiring process improvements, and documents corrective actions taken to address non-conformances discovered during audits.

Construction companies conduct safety inspections at job sites, checking compliance with OSHA regulations, verifying proper PPE usage, and identifying hazardous conditions before accidents occur. Digital checklists ensure consistent safety protocols across multiple projects while providing photo documentation of violations for contractor accountability.

Food service facilities perform health and safety audits covering HACCP requirements, temperature monitoring, sanitation procedures, and food handling practices. The system maintains compliance records required for health department inspections while tracking corrective actions for violations that could result in regulatory citations or facility closures.

Conclusion

Building an inspection app without coding transforms quality management from reactive firefighting into proactive compliance assurance. Custom solutions eliminate paper-based inefficiencies while providing:

Standardized inspection procedures across all locations and inspectors

Real-time visibility into quality issues and safety violations

Automated corrective action tracking with accountability

Complete audit trails for regulatory compliance

Data-driven insights for continuous quality improvement

No-code development empowers quality professionals to design inspection systems matching their exact standards, workflows, and reporting requirements without IT dependencies or expensive consultants.

Ready to eliminate paper checklists and improve compliance? Create your account and start building a custom inspection app tailored to your quality standards. Explore powerful features and discover flexible pricing that scales with your organization.

Related Articles: